|

|

|

|

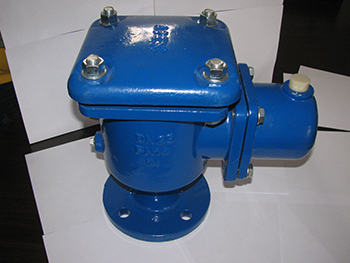

Flange exhaust valve is a barrel valve body, which mainly contains group B stainless steel balls, rods and plugs. Flange exhaust valves are usually installed at the pump outlet or in the distribution pipeline to remove a large amount of accumulated air in the pipeline, or to discharge trace air accumulated at the higher part of the pipeline to the atmosphere, so as to improve the efficiency of the pipeline and pumps. Once there is negative pressure in the pipeline, the valve quickly inhales external air to protect the pipeline from damage caused by negative pressure.

1. The float of the exhaust valve is made of low density PPR and composite material, which will not deform even if immersed in high temperature water for a long time. It will not make the float difficult to move.

2. The lever of the buoy is made of hard plastic, and the connection between the lever and the buoy and the support is made of movable connection. Therefore, it will not cause rust in long-term operation, which will lead to water leakage when the system can not work.

3. The sealing end of the lever is supported by spring, which can expand and contract with the movement of the lever to ensure the sealing without exhaust.